How Regular Welding Inspection Madison Can Conserve You Money And Time

How Regular Welding Inspection Madison Can Conserve You Money And Time

Blog Article

Exactly How Efficient Welding Assessment Boosts Architectural Honesty and Longevity

In the world of building and engineering, the relevance of welding assessment can not be overstated, as it plays a crucial function in ensuring architectural integrity and expanding the lifespan of tasks. Join the expedition of how reliable welding assessments can change prospective susceptabilities into strengths, adding to the enduring success of buildings.

Value of Welding Inspection

Making certain the structural stability and safety of welded building and constructions mandates strenuous welding inspection procedures. Welding inspection serves as a crucial protect in the building and construction and manufacturing markets, where the toughness and resilience of joints dramatically impact the general efficiency of frameworks. This inspection makes sure that welds fulfill specific requirements and specs, decreasing the threats associated with structural failures. The repercussions of poor welds can be catastrophic, resulting in expensive fixings, functional downtimes, or even devastating failures, all of which highlight the vital relevance of extensive assessment.

In addition to safety, welding evaluation plays a vital role in top quality guarantee. By sticking to fixed criteria, inspections ascertain the uniformity of welds, making sure that each satisfies the desired toughness and visual demands. This consistency is essential not just for security but additionally for keeping the credibility and integrity of suppliers and fitters. Regulatory conformity is a substantial chauffeur of welding assessment practices. Market standards and codes, such as those from the American Welding Culture (AWS) or the International Organization for Standardization (ISO), require adherence to strict guidelines, emphasizing the value of inspections in satisfying these specialist and legal responsibilities.

Secret Assessment Strategies

Ultrasonic Evaluating (UT) uses high-frequency acoustic waves to discover subsurface imperfections, offering exact details about weld integrity without triggering any kind of damages. Radiographic Testing (RT), involving X-rays or gamma rays, offers an in-depth picture of the weld's internal framework, revealing surprise blemishes. Magnetic Bit Evaluating (MPT) is one more non-destructive method, especially reliable for identifying surface area and near-surface interruptions in ferromagnetic materials.

Penetrant Screening (PT) entails the application of a liquid color to reveal surface-breaking defects, providing a simple and economical remedy for non-porous products. Each strategy has its details applications, toughness, and constraints, and usually a mix of approaches is used to accomplish detailed assessment results. Mastery of these techniques enhances the integrity and durability of bonded frameworks, lining up with safety and performance assumptions.

Identifying Common Flaws

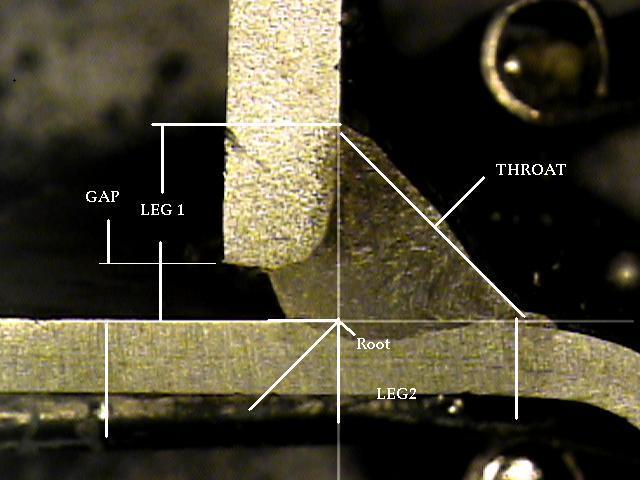

Porosity, defined by gas pockets within the weld, lowers the weld's strength and sturdiness. Splits, which can take place during or after welding, position considerable threats due to their potential to propagate under tension.

Incomplete fusion, where the weld steel falls short to bond entirely with the base product, threatens the architectural stability, leading to weak joints. Slag additions happen when non-metallic materials are trapped in the weld, endangering its toughness and top quality.

Determining these problems through meticulous inspection approaches, such as aesthetic assessment, ultrasonic testing, or radiography, is important. Dealing with these concerns ensures weld top quality, eventually supporting the structural integrity and safety and security of the constructed setting.

Enhancing Structural Efficiency

Comprehending the value of determining common weld flaws naturally causes exploring techniques for boosting structural efficiency. The fundamental method for boosting performance involves using advanced welding methods and products that reduce flaw occurrence. Using high-grade filler materials and making sure correct heat control can considerably reduce issues such as porosity and splitting, thereby improving the weld's honesty.

Including cutting edge welding innovations, such as laser welding and rubbing mix welding, their website further enhances architectural strength. These strategies offer superior accuracy and lowered thermal distortion, directly impacting the sturdiness and toughness of the bonded frameworks. Taking on automated welding systems can make certain repeatable and consistent weld quality, reducing human error.

Additionally, executing rigorous pre-weld and post-weld procedures is essential. Proper joint design, surface prep work, and stress-relieving procedures add to optimum weld efficiency. Carrying out complete pre-weld assessments enables early detection of potential concerns, facilitating prompt corrections before they endanger the structure.

Long-lasting Advantages of Inspection

With cautious evaluation methods, the lasting benefits to structural stability come to be significantly evident. Thorough and consistent welding assessments play a crucial role in avoiding structural failings by recognizing disparities and flaws early in the building and construction procedure.

In addition, regular inspections add to maintaining compliance with industry standards and regulations, thus preventing monetary and legal consequences. This adherence to high quality assurance not try this out only boosts the dependability of the framework but likewise promotes count on among stakeholders, including clients, designers, and regulatory bodies. The detailed paperwork of assessment results functions as a useful resource for future maintenance and fixing initiatives, promoting notified decision-making.

Furthermore, effective inspection techniques sustain development by incorporating advanced modern technologies such as non-destructive testing and digital imaging, which can boost precision and efficiency. This technical combination even more underscores the dedication to excellence in structural honesty. Eventually, buying careful welding evaluations is a sensible method that yields significant long-lasting advantages, securing both the economic and physical investment in framework jobs.

Verdict

Efficient welding inspection plays a crucial duty in improving architectural integrity and durability by identifying flaws early in the construction procedure. Making use of methods such as aesthetic evaluation, ultrasonic screening, and radiographic screening guarantees the discovery of issues like fractures and porosity that endanger weld strength. Extensive examinations guarantee conformity with industry standards, consequently lengthening the lifespan of frameworks, decreasing costly repair services, and cultivating stakeholder count on the dependability and safety and security of bonded building and constructions.

In the world of construction and engineering, the value of welding examination can not be overstated, as it plays an essential duty in ensuring structural see this stability and prolonging the life expectancy of tasks.Ensuring the structural integrity and safety of welded buildings mandates extensive welding assessment procedures.Structure upon the value of welding examination in safeguarding structural integrity, understanding the key evaluation methods ends up being critical for reliable execution. Reliable welding examination incorporates an array of techniques created to examine weld high quality, guaranteeing compliance with stringent design criteria - Welding Inspection Madison.Efficient welding assessment plays a vital function in enhancing architectural honesty and durability by identifying defects early in the building and construction procedure

Report this page